Maximize Your Welding High Quality with Specialist Inspection Services in Gilbert Arizona

Maximize Your Welding High Quality with Specialist Inspection Services in Gilbert Arizona

Blog Article

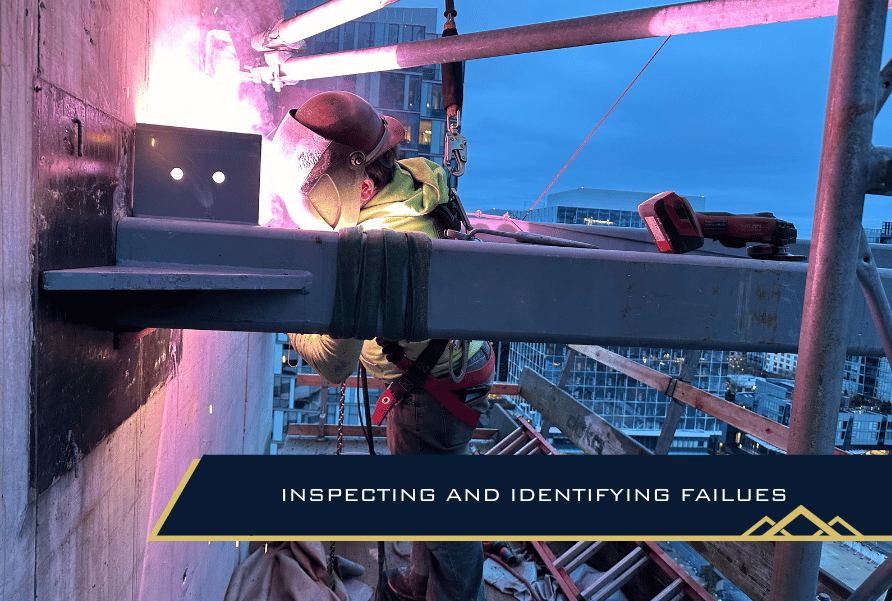

Welding Assessment Demystified: Trick Processes, Tools, and the Vital Function They Play in Keeping High-Quality Welds

Welding evaluation offers as a critical foundation in the assurance of architectural honesty and top quality in bonded joints, affecting various markets from building and construction to production. What are the essential processes and tools that make certain these criteria are supported?

Value of Welding Evaluation

Making certain the honesty of welded joints is vital in different sectors, making the significance of welding evaluation undeniable. The high quality of welds straight impacts the safety and security, performance, and long life of elements and structures. In sectors such as building, auto, aerospace, and manufacturing, any kind of failure in welded joints can result in devastating repercussions, consisting of architectural failures, devices malfunction, and death.

Welding assessment acts as a vital quality assurance step, ensuring that welds fulfill specified requirements and regulative requirements. It identifies issues such as splits, porosity, and insufficient fusion that might jeopardize the strength of the weld. By identifying these problems early, welding inspection can avoid pricey rework, delays, and potential safety dangers.

In addition, welding inspection promotes compliance with industry criteria and qualifications, enhancing the trustworthiness of organizations and their items. It also sustains constant renovation by supplying beneficial feedback to welding workers, allowing them to improve their processes and methods.

Eventually, the value of welding evaluation can not be overemphasized; it is necessary for preserving high-grade welds, making sure safety, and securing investments throughout numerous industries.

Secret Examination Processes

Efficient welding inspection counts on a series of vital procedures created to assess the quality and integrity of welds. These processes incorporate both non-destructive and aesthetic testing (NDT) methods, guaranteeing that any flaws are recognized prior to they jeopardize structural honesty.

The very first step in the assessment process is a thorough visual assessment, which allows assessors to assess welds for surface issues such as cracks, undercuts, and insufficient combination. Complying with aesthetic checks, various NDT techniques might be utilized, including ultrasonic screening, magnetic bit screening, and radiographic testing. Each method uses distinct advantages; for circumstances, ultrasonic testing can detect inner defects, while radiographic screening provides a permanent record of the weld's inner structure.

Furthermore, it is essential to confirm conformity with relevant codes and standards, ensuring that the weld fulfills sector specifications. This consists of inspecting weld measurements and positioning, as incorrect dimensions can result in failures under tons.

Crucial Tools for Examination

On a regular basis making use of the right devices is important for achieving exact welding inspections. A detailed set of evaluation devices assists make sure that welds fulfill rigid top quality standards and specifications.

One of the main tools is the visual evaluation gauge, which permits assessors to examine surface area conditions, such as cleanliness and surface finish, straight. Furthermore, micrometers and calipers are necessary for gauging weld dimensions and ensuring they satisfy required resistances.

For more comprehensive assessments, ultrasonic screening (UT) equipment is important. This method site utilizes high-frequency sound waves to identify interior imperfections and analyze product density. In a similar way, magnetic particle screening (MT) and dye penetrant testing (PT) are crucial for determining surface and near-surface defects, providing instant aesthetic signs of possible concerns.

Welders should likewise be equipped with solidity testers, which examine the mechanical residential properties of the weld metal and base products, ensuring they fulfill specific demands. Recording findings with digital evaluation devices boosts traceability and high quality control. By utilizing these important tools, inspectors can preserve top quality welds, inevitably adding to the safety and integrity of welded structures.

Usual Flaws and Their Detection

Welds, akin to the foundation of structural stability in construction and production, can display different problems that endanger their efficiency and security. Usual defects consist of porosity, cracks, undercut, lack of blend, and slag incorporations (Welding Inspection Gilbert Arizona). Each of these view it problems can materialize as a result of incorrect welding methods, inadequate material selection, or insufficient prep work

Detection of these issues can be attained with various non-destructive screening approaches, consisting of visual examination, ultrasonic screening, and radiographic testing. Each approach plays an essential role in recognizing these mistakes, making sure that the honesty of the weld is preserved and decreasing the threat of failure in essential applications.

Ideal Practices for Top Quality Assurance

Guaranteeing the finest of welds is extremely important for structural integrity and safety, specifically in markets where the consequences of failure can be severe. To achieve this, numerous best techniques for high quality assurance have to be applied throughout the welding process.

First, a durable welding treatment spec (WPS) ought to be developed, detailing the needed parameters for each welding operation. This guarantees uniformity and adherence to sector standards. Second, complete training and qualification of welders are necessary; competent employees are better outfitted to produce high-quality welds and identify potential defects.

Regular evaluations ought to be integrated right into the welding procedure, utilizing both non-destructive and visual screening (NDT) methods to identify next page flaws beforehand. Regular calibration of examination devices is important to keep precision. In addition, documenting all welding tasks, consisting of evaluations and corrective activities, produces a deducible document that can be very useful for top quality control.

Verdict

Finally, welding examination functions as an essential system for making sure the honesty and dependability of welded joints across sectors - Welding Inspection Gilbert Arizona. Via the execution of crucial evaluation procedures and the usage of necessary tools, companies can successfully determine and deal with possible issues. Adherence to finest practices in high quality guarantee not only boosts security but also makes sure conformity with sector requirements, inevitably adding to the longevity and performance of components and structures

Welding assessment offers as a critical foundation in the assurance of architectural stability and quality in welded joints, affecting numerous markets from building and construction to manufacturing.Ensuring the integrity of bonded joints is vital in different sectors, making the value of welding assessment obvious.Welding evaluation serves as an important high quality control procedure, guaranteeing that welds meet specified standards and governing requirements. By using these essential devices, assessors can maintain high-grade welds, inevitably contributing to the safety and security and dependability of bonded frameworks.

In verdict, welding examination serves as a crucial system for guaranteeing the honesty and integrity of bonded joints across markets.

Report this page